|

At Milpitas Unified, we're at the beginning phases of incorporating 3D printing into our learning process. One of 3D printing pain points is the removal of support material. This solves that issue.

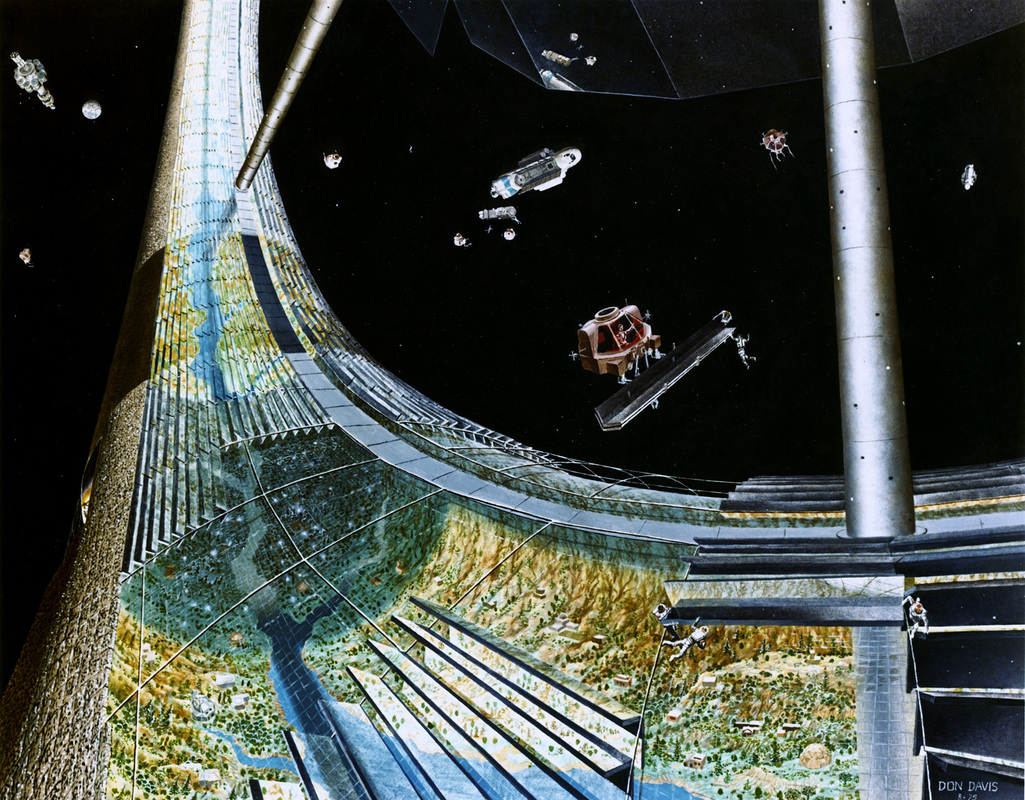

Explore more @ Cubify Although space policy and international affairs is not a commonly talked about majors in K-12, it will be important for our students and teachers to build a greater awareness towards space topics.

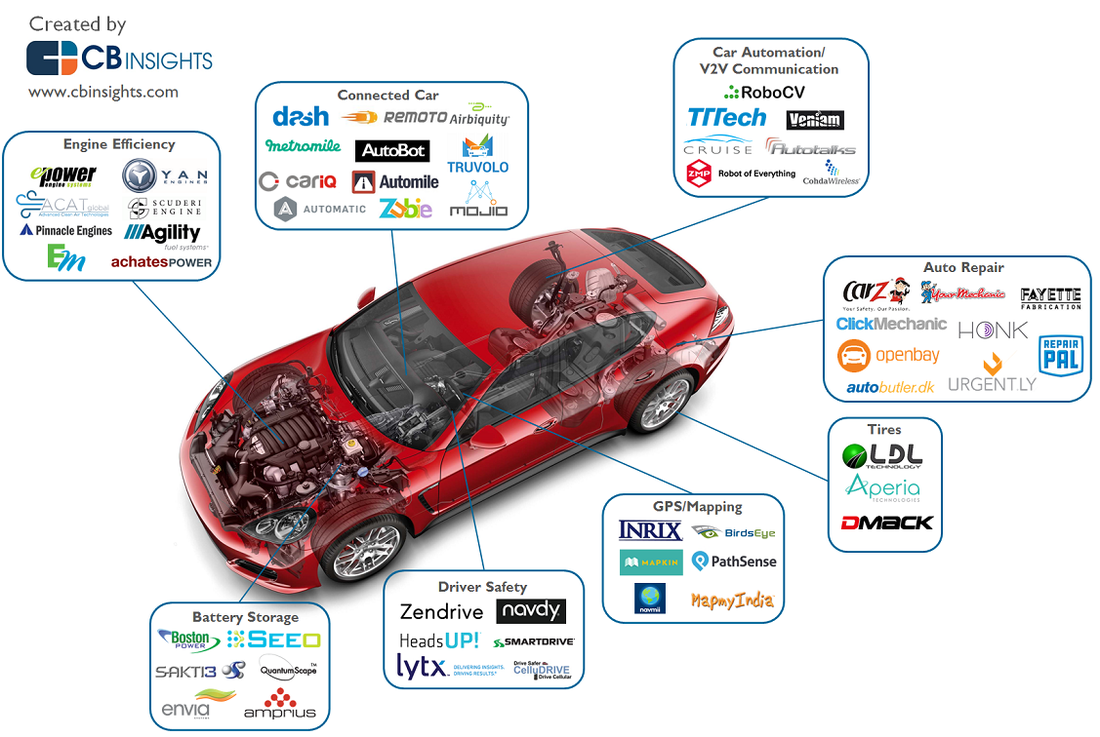

----- "Henry Hertzfeld, a professor of Space Policy and International Affairs at George Washington University, has taught a space law course for 11 years (before that, his background was in economics—the regular Earth kind). Even though the laws that govern space were drawn up back in the 1960s and 1970s, they’re still very good, he says. “The whole idea is freedom of access and using space for..." Read on @ Gizmodo How many of these companies are you familiar with? If these companies still exist, our students may develop and market their next generation products.

Read more at CB Insights Milpitas Unified embarked on our journey to build our new elementary school and with our student, staff, parent, and community input, we will see the realization of the question: "If you could build any school, what would you build?"

----- "When I got the call 18 months ago from Achievement First to help design a “next-generation” school model, it was a school designer’s dream. Achievement First has been running great schools serving low-income kids in New York, Connecticut, and Rhode Island for 15 years. They embodied the profile of the “successful incumbent”: well-established schools which rarely want to take big innovation risks. And yet, a place like Achievement First has built such incredible wisdom and capacity for running great schools, what might it mean to combine that wisdom with a fresh approach to doing school? And so, we began our journey to design and build the “Greenfield” model. Imagine an open, green field with nothing on it; if you could build any school what you build?" Read more on edSurge

"At the International Manufacturing Technology Show in Chicago, Local Motors 3D printed a plastic car called the Strati. Local Motors printed the car's chassis and body all in one piece, and also printed the fenders separately. The first phase of the process took just 44 hours.

Then the non-printed components (engine, seats, steering wheel, etc.) were..." Read more at Business Insider |

Shared ThoughtsTogether, as learners in the education space, we would like to share a selection of what we read and reflect on internally. Categories

All

Archives

January 2016

|

Milpitas Unified School District

|

|

RSS Feed

RSS Feed